The Double Eccentric Butterfly Valve is an advanced type of valve designed to control the flow of fluids in various industrial applications. It features a unique design with two eccentricities in its construction, ensuring a tight seal and reduced wear during operation. This valve type is known for its ability to provide excellent flow control with minimal torque requirements, making it ideal for applications involving high flow rates and challenging conditions. The double eccentricity also helps minimize seat wear and enhances its lifespan, ensuring reliable performance over time.

A Double Eccentric Butterfly Valve is engineered for precision and efficiency in regulating fluid flow. Unlike traditional butterfly valves, this design incorporates two offset axes, which reduces friction between the valve’s seal and the seat during operation. The result is a smoother opening and closing motion, lower pressure drops, and improved durability. Commonly used in industries such as water treatment, oil, and gas, the double eccentric design allows for a robust solution where performance, longevity, and ease of maintenance are essential.

Double Eccentric Butterfly Valve Valve is trusted across various industries for its precision, durability, and reliability. Explore its wide-ranging applications below:

Double Eccentric Butterfly Valves are used in pipelines, refineries, and offshore platforms for reliable flow control, offering minimal leakage and high-pressure resistance in extreme conditions.

In water treatment plants, dams, and municipal systems, Double Eccentric Butterfly Valves ensure efficient flow regulation, providing excellent sealing for isolation and pressure control.

Double Eccentric Butterfly Valves play a vital role in power plants, controlling the flow of steam, cooling water, and other fluids in thermal and hydroelectric systems with minimal torque and enhanced durability.

For chemical processing, Double Eccentric Butterfly Valves offer precise flow control for aggressive chemicals, acids, and gases, ensuring safety and reliability in corrosive and hazardous environments.

In the marine and shipbuilding sectors, Double Eccentric Butterfly Valves are used for fluid management, ballast control, and system regulation, performing reliably in harsh maritime conditions.

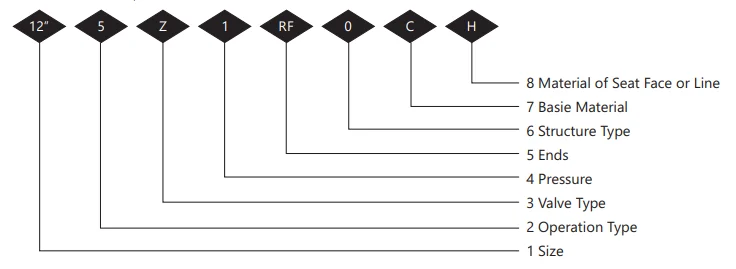

| 1 | Size | The inch series is expressed with xxin; the metric series is expressed with xx, with the unit mm omitted | |||||

| 2 | Operation Type | 1-Bare Stem | 3-Worm Gear Operated | 6**-Air Operated | 7◎-Hydraulic Operated | 9-Electric Operated | Hand Operated (Omit) |

| 3 | Valve Type | D - Butterfly Valve DH - Check Butterfly Valve Dx - Vacuum Butterfly Valve Dk - Aeration Butterfly Valve Ds - Flexible Butterfly Valve | |||||

| 4 | Pressure | 0a-PN6 | 0b-PN2.5 | 0-PN10 | 1-PN16 Class150 | 2-PN25 | 3-Class300 |

| 4-PN40 Class400 | 6-PN64 Class600 | 9-Class900 | 10-PN100 | 1a-Class125 | 2a-Class250 | ||

| 5 | Ends | RF - Raised Face | FF - Flat Face | MFM - Male and Female Face | RJ - Ring Joint | BW - Butt-Weld WS - Wafer with 4 lugs WL - Wafer with no lug WF - Single Reinforcement Wafer Type WU - Unthreaded Hole Wafer Type LL - Full Lug Screw Wafer Type LU - U Screw Wafer Type | |

| 6 | Structure Type | 1-Middle Eccentric Structure | 2-Single Eccentric Structure | 3-Double Eccentric Structure | 4-Variable Eccentric Structure | 5-Three Eccentric Structure | |

| 7 | Basic Material | C-WCB | C-C5 | C6-WC6 | C9-WC9 | BL-LCB | CL-LCC |

| 8-CF8 | 8M-CF8M | 3-CF3 | 3M-CF3M | ML-MONEL | H-IRON | ||

| 8 | *Material of Seat Face of Liner | H-Cr13S.S | E-18-8S.S | R-Mo2Ti S.S | F-PTFE | - | - |

| D-Nitriding Steel | M-Monel Alloy | Y-Hard Face | X-Rubber | - | - | ||

Butterfly valves are used to open and close (seal type) or adjust the medium flow in pipes in the fields of foodstuff, drinks, chemical, industrial water treatment, high-rise constructions, water supply and drainage etc.. They are mainly structured as following

1. Simple structure, small sizes, light weight and low installation dimensions. According to the types of body connection, they are basically classified to wafer type (including lug wafer type), flanged and welded.

2. Sealing materials may be soft hard, placed on body or disc, to meet different working conditions, and to effect good seal and long lift.

(a). Soft sealing structure (see fig. right), is applicable for single and double eccentric butterfly valves, pressure rating <CLASS 600. Centred sealing structure is applicable for pressure rating <CLASS 250. Sealing ring (PTFE) is placed on the valve body to feature the following.

(b). Multilayer hard seal structure is applicable for single, double and triple eccentric butterfly valves, pressure rating<CLASS 600. And, triple eccentric butterfly valve can maintain two-way leak-tightness. Multilayer sealing ring is composite of stainless steel and nonmetal material. The nonmetal material can be flex-ible graphite, PTFE or non asbestos material etc. according to he actual working conditions. (See fig. right)

3. Elastic ring hard seal structure (see fig. right) is of the structure of J-type metal sealing ring. It is applicable for single and double eccentric butterfly valves, pressure rating <CLASS 300, Prov-ided with fireproof structure to adapt to conditions with great temperature changes, it is featured by outstanding seal. Long service life and easy workmanship.

4. Fireproof butterfly valves (see fig. Right) can stop the expansion of fire, Once the sealing seat of butterfly valves is on fire, the stainless Steel sealing ring will act to make butterfly valve immediately sealed.

5. Low driving moment, easy and quick operation.

The rotation center of disc (namely the center of valve shaft) and the centerline of body form up a ‘b’ eccentric on the base of single eccentric butterfly valve, making the sealing face of disc disengaged from seat sealing face more quickly than single eccentric seal butterfly O O valves during the process of open and close. Once disc turns to 8 -12 , the disc sealing face will be completely disengaged from the seat sealing face. Once fully opened, a gap ‘Y’ will be formed up between the two sealing faces. This type of butterfly valves are designed to have greatly lowered the mechanical wear and extrusion deformation between the two sealing faces, making the sealing performance of butterfly valve much better.

The characteristic of this structure is to make stem axis not only deviated from the center of disc, but also the center or the body. The effect of double eccentric is that, when valve has been opened, disc can be quickly disengaged from seat, thus to greatly eliminate the unnecessary excessive extrusion and scratch between the disc and seat, reduce opening resistance, lower the abrasion and improve the service life of seat. As scratch has been greatly lowered, metal seat can be used for double eccentric butterfly valve, so that butterfly valves are able to be used in high temperature fields. However, as its seal is positioned sealing construction, i.e. the sealing faces disc and seat is lineal contact, disc extruding seat to produce elastic deformation, thus to effect the sealing performance. This has high requirement on close position, especially for those with metal seat, and is given poor pressure endurance. This is why butterfly valves are, conventionally, not resistant to high temperature and leakage.

1. Disc closed, medium enters from the upstream of seat. Under the force of medium, sealing ring will get close to the sealing face of disc, and the elasticity and deformation of sealing ring will function to guarantee the sealing performance.

2. Disc closed, medium enters from teh downstream of seat. Under the extrusion of press board ring. sealing will overcome the acting force of medium and get close to the sealing face of disc. thus to guarantee the sealing performance.

High Performance Fire-safe Butterfly Valve Torques (NM)

| Size | Pressure | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| DN(mm) | NPS | 100 PSI | 150 PSI | 200 PSI | 285 PSI | 400 PSI | 600 PSI | 740 PSI | 1000 PSI | 1200 PSI | 1480 PSI |

| 50 | 2" | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 65 | 2½" | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 80 | 3" | 67 | 87 | 107 | 116 | 134 | 147 | 179 | 195 | 228 | 302 |

| 100 | 4" | -- | 130 | 169 | 228 | -- | -- | -- | -- | -- | -- |

| 125 | 5" | -- | 198 | 297 | 424 | 453 | 511 | 559 | 606 | 608 | 856 |

| 150 | 6" | -- | 463 | 531 | 680 | 870 | 1039 | 1314 | 1621 | 1909 | |

| 200 | 8" | -- | 610 | 815 | 1037 | 1192 | 1401 | 2024 | 3027 | 4021 | |

| 250 | 10" | -- | 936 | 1328 | 1780 | 1907 | 2121 | 2288 | 3576 | 4221 | 5011 |

| 300 | 12" | -- | 1644 | 1743 | 1829 | 2754 | 3841 | 4604 | 5666 | 6305 | 6803 |

| 350 | 14" | -- | 2306 | 4567 | 6498 | 7828 | 9457 | 11092 | -- | -- | -- |

| 400 | 16" | 2813 | 2017 | 3220 | 5491 | 7813 | 9939 | -- | -- | -- | -- |

| 450 | 18" | 3603 | 3888 | 7698 | 11025 | 16157 | 18383 | -- | -- | -- | -- |

| 600 | 24" | 5722 | 6547 | 17184 | 20495 | 26769 | -- | -- | -- | -- | -- |

| 700 | 28" | 8022 | 11510 | 13118 | 25376 | 37002 | -- | -- | -- | -- | -- |

| DN (mm) | NPS | 100 PSI | 200 PSI | 285 PSI | 300 PSI | 400 PSI | 600 PSI | 740 PSI | 1200 PSI | 1480 PSI |

|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 2" | -- | -- | 37 | -- | -- | -- | -- | -- | -- |

| 65 | 2½" | 31 | 39 | 46 | 47 | 55 | 71 | 82 | 95 | 142 |

| 80 | 3" | 43 | 54 | 64 | 66 | 77 | 100 | 115 | 133 | 199 |

| 100 | 4" | 83 | 111 | 134 | 138 | 166 | 222 | 261 | 305 | 333 |

| 125 | 5" | 125 | 167 | 202 | 208 | 250 | 333 | 391 | 458 | 700 |

| 150 | 6" | 188 | 250 | 304 | 313 | 375 | 500 | 588 | 687 | 778 |

| 200 | 8" | 363 | 476 | 572 | 589 | 702 | 929 | 1087 | 1268 | 1409 |

| 250 | 10" | 602 | 806 | 1010 | 1015 | 1215 | 1623 | 1909 | 2236 | 2862 |

| 300 | 12" | 910 | 1250 | 1538 | 1589 | 1929 | 2609 | 3084 | 3628 | 4579 |

| 350 | 14" | 1052 | 1411 | 1715 | 1767 | 2127 | 2844 | 3346 | 4824 | 5357 |

| 400 | 16" | 1317 | 1758 | 2133 | 2199 | 2640 | 3522 | 4139 | 8202 | 9124 |

| 450 | 18" | 1817 | 2488 | 3058 | 3159 | 3830 | 5172 | 6111 | 9893 | 11005 |

| 500 | 20" | 2501 | 3346 | 4064 | 4191 | 5037 | 6726 | 7910 | 13999 | 15569 |

| 600 | 24" | 3496 | 4698 | 5719 | 5900 | 7102 | 9505 | 11188 | 21467 | 23885 |

| 700 | 28" | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 750 | 30" | 4949 | 6678 | 8021 | 9169 | 12451 | 18157 | 22156 | -- | -- |

| 800 | 32" | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 900 | 36" | 5982 | 8406 | 10151 | -- | -- | -- | -- | -- | -- |

| 1000 | 40" | -- | -- | -- | -- | -- | -- | -- | -- | -- |

| 1050 | 42" | 9525 | 12609 | 16698 | -- | -- | -- | -- | -- | -- |

| 1200 | 48" | 14914 | 20506 | 25260 | -- | -- | -- | -- | -- | -- |

Flow coefficient is and index to measure the flow capacity of valve. The more the flow coefficient is, the less the pressure loss upon fluid flowing through the valve. The values of flow coefficient differ from the sizes, types and structures of valves. Valve of different types and specifications should be separately tested to make certain of its value of flow coefficient. For valves of the same structure, the valve of flow coefficient differs according to the directions of fluid through the the valves. The differences is usually caused by the difference in pressure recovery. The table below is the flow coefficient of double eccentric butterfly valve, used for reference to choose valve flow coefficient. Cv means the American O O gallons of +60 F(+16 C) water flowing through the valve per minute under 1 pound/inch2(0.006894757Mpa) pressure drop.

| Size | Pressure | Degree Open (°C) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10°C | 20°C | 30°C | 40°C | 50°C | 60°C | 70°C | 80°C | 90°C | ||

| 2" | 150 | 1.5 | 6 | 14 | 25 | 39 | 56 | 76 | 99 | 102 |

| 300 | 1.4 | 5 | 13 | 24 | 36 | 52 | 71 | 95 | 100 | |

| 600 | 1.4 | 5 | 13 | 23 | 35 | 51 | 70 | 90 | 93 | |

| 2½" | 150 | 2.2 | 9 | 21 | 37 | 56 | 80 | 110 | 142 | 146 |

| 300 | 2.1 | 8 | 19 | 34 | 52 | 75 | 102 | 136 | 143 | |

| 600 | 2.0 | 8 | 19 | 33 | 51 | 73 | 100 | 130 | 133 | |

| 3" | 150 | 3.4 | 14 | 32 | 57 | 87 | 125 | 171 | 221 | 228 |

| 300 | 3.2 | 13 | 30 | 53 | 81 | 117 | 159 | 212 | 223 | |

| 600 | 3.1 | 12 | 29 | 52 | 79 | 114 | 156 | 202 | 208 | |

| 4" | 150 | 6.8 | 27 | 63 | 114 | 171 | 248 | 338 | 437 | 451 |

| 300 | 6.2 | 25 | 58 | 104 | 157 | 228 | 310 | 414 | 435 | |

| 600 | 5.8 | 23 | 54 | 98 | 147 | 213 | 290 | 375 | 387 | |

| 5" | 150 | 10.8 | 43 | 100 | 180 | 271 | 392 | 535 | 692 | 714 |

| 300 | 9.8 | 40 | 92 | 165 | 248 | 361 | 491 | 655 | 688 | |

| 6" | 150 | 16.5 | 66 | 154 | 278 | 419 | 607 | 827 | 1070 | 1103 |

| 300 | 14.9 | 60 | 139 | 250 | 377 | 546 | 744 | 992 | 1041 | |

| 600 | 14.7 | 59 | 137 | 247 | 372 | 538 | 734 | 950 | 979 | |

| 8" | 150 | 30.9 | 124 | 289 | 520 | 784 | 1135 | 1584 | 2002 | 2064 |

| 300 | 27.9 | 109 | 255 | 459 | 692 | 1001 | 1365 | 1820 | 1911 | |

| 600 | 26.8 | 107 | 250 | 451 | 679 | 983 | 1341 | 1734 | 1788 | |

| 10" | 150 | 52.8 | 211 | 492 | 886 | 1336 | 1934 | 2638 | 3411 | 3517 |

| 300 | 45.6 | 183 | 426 | 767 | 1156 | 1673 | 2282 | 3042 | 3194 | |

| 600 | 41.2 | 165 | 384 | 692 | 1044 | 1511 | 2060 | 2665 | 2747 | |

| 12" | 150 | 72.6 | 290 | 677 | 1219 | 1838 | 2660 | 3628 | 4690 | 4837 |

| 300 | 63.3 | 253 | 590 | 1063 | 1602 | 2319 | 3163 | 4217 | 4428 | |

| 600 | 58.4 | 233 | 545 | 981 | 1479 | 2140 | 2918 | 3774 | 3891 | |

| 14" | 150 | 90 | 293 | 492 | 886 | 1336 | 1934 | 2638 | 3411 | 3517 |

| 300 | 81 | 326 | 760 | 1368 | 2063 | 2986 | 4072 | 5430 | 5702 | |

| 600 | 73 | 292 | 682 | 1228 | 1838 | 2680 | 3655 | 4727 | 4873 | |

| 16" | 150 | 132 | 531 | 1230 | 2229 | 3361 | 4865 | 6634 | 8845 | 9287 |

| 300 | 109 | 435 | 1015 | 1827 | 2755 | 3988 | 5438 | 7850 | 8243 | |

| 600 | 96 | 385 | 899 | 1619 | 2423 | 3533 | 4818 | 6231 | 6424 | |

| 18" | 150 | 171 | 684 | 1596 | 3873 | 4332 | 6270 | 8550 | 11270 | 11400 |

| 300 | 139 | 555 | 1295 | 2331 | 3515 | 5088 | 6938 | 9250 | 9712 | |

| 20" | 150 | 207 | 828 | 1932 | 3478 | 5244 | 7590 | 10350 | 13800 | 14420 |

| 300 | 158 | 630 | 1470 | 2646 | 3990 | 5775 | 7875 | 10150 | 10658 | |

| 24" | 150 | 315 | 1260 | 2940 | 5292 | 7890 | 11550 | 15750 | 21000 | 22050 |

| 300 | 242 | 966 | 2254 | 4057 | 6118 | 8855 | 12075 | 16100 | 16205 | |

| 30" | 150 | 491 | 1965 | 4585 | 8253 | 12445 | 18012 | 24563 | 32750 | 34388 |

| 300 | 404 | 1614 | 3766 | 6779 | 10222 | 14795 | 20175 | 26900 | 38145 | |

| 36" | 150 | 707 | 2830 | 6602 | 11884 | 17920 | 25938 | 35370 | 45745 | 47160 |

| 42" | 150 | 963 | 3851 | 8987 | 16176 | 24392 | 35304 | 48143 | 62264 | 64190 |

| 48" | 150 | 1258 | 5030 | 11738 | 21128 | 31859 | 46111 | 62881 | 81324 | 83840 |

| DN | NPS | PN0.25 | PN0.6 | PN1.0 | PN1.6 | PN2.5 | PN4.0 | Class150 |

|---|---|---|---|---|---|---|---|---|

| 80 | 3" | -- | -- | -- | 291 | 291 | -- | 291 |

| 100 | 4" | -- | -- | -- | 413 | 413 | -- | 413 |

| 125 | 5" | -- | -- | -- | 903 | 903 | -- | 903 |

| 150 | 6" | -- | -- | -- | 1150 | 1120 | -- | 1020 |

| 200 | 8" | -- | -- | -- | 2640 | 1830 | 1660 | 1830 |

| 250 | 10" | -- | -- | -- | 4110 | 3710 | 2570 | 3710 |

| 300 | 12" | -- | -- | -- | 7030 | 5620 | 3710 | 5620 |

| 350 | 14" | -- | -- | -- | 9620 | 7460 | 5250 | 7460 |

| 400 | 16" | -- | 16100 | 14000 | 9620 | 7460 | 5250 | 7460 |

| 450 | 18" | -- | 20900 | 18700 | 15800 | 12300 | 9430 | 12300 |

| 500 | 20" | -- | 26600 | 24100 | 19500 | 15200 | 11600 | 15200 |

| 600 | 24" | -- | 38300 | 34700 | 28200 | 21900 | 16700 | 21900 |

| 700 | 28" | 53500 | 52100 | 47300 | 38400 | 29800 | 24100 | 29800 |

| 750 | 30" | 61400 | 59800 | 54300 | 44000 | 34200 | 27600 | 34200 |

| 800 | 32" | 68000 | 66800 | 61800 | 50100 | 39000 | 32300 | 39000 |

| 900 | 36" | 91000 | 86100 | 78300 | 64400 | 49700 | -- | 49700 |

| 1000 | 40" | 119000 | 106000 | 96500 | 79400 | 68300 | -- | 68300 |

| 1100 | 44" | 150000 | 129000 | 117000 | -- | -- | -- | -- |

| 1200 | 48" | 178000 | 153000 | 139000 | -- | -- | -- | -- |

| 1300 | 52" | 209000 | 179000 | 163000 | -- | -- | -- | -- |

| 1400 | 56" | 242000 | 208000 | 190000 | -- | -- | -- | -- |

| 1500 | 60" | 278000 | 239000 | 218000 | -- | -- | -- | -- |

| 1600 | 64" | 317000 | 271000 | 247000 | -- | -- | -- | -- |

| 1800 | 72" | 401000 | 344000 | 328000 | -- | -- | -- | -- |

| 2000 | 80" | 495000 | 449000 | 414000 | -- | -- | -- | -- |

| 2400 | 96" | 739000 | 689000 | 628000 | -- | -- | -- | -- |

| 2600 | 104" | 868000 | 837000 | -- | -- | -- | -- | -- |

| 2800 | 112" | 1010000 | 970000 | -- | -- | -- | -- | -- |

| 3000 | 120" | 1210000 | 1110000 | -- | -- | -- | -- | -- |

| 3200 | 128" | 1370000 | -- | -- | -- | -- | -- | -- |

| 3200 | 128" | 1540000 | -- | -- | -- | -- | -- | -- |

| 3600 | 144" | 1810000 | -- | -- | -- | -- | -- | -- |

| 3600 | 152" | 2010000 | -- | -- | -- | -- | -- | -- |

| 4000 | 160" | 2230000 | -- | -- | -- | -- | -- | -- |

1. The butterfly valve with flow coefficient in the table above is soft seal structure with sealing ring mounted on the disc.

2. DN>400, two-piece structure of valve shaft.

| DN | NPS | PN0.25 | PN0.6 | PN1.0 | PN1.6 | PN2.5 |

|---|---|---|---|---|---|---|

| 150 | 6" | -- | 739 | 739 | 536 | 454 |

| 200 | 8" | -- | 1860 | 1440 | 1100 | 1040 |

| 250 | 10" | -- | 2930 | 2350 | 2350 | 1840 |

| 300 | 12" | -- | 5070 | 4390 | 3730 | 2880 |

| 350 | 14" | 8390 | 7040 | 6250 | 5640 | 4040 |

| 400 | 16" | 11100 | 10400 | 8560 | 7410 | 5700 |

| 450 | 18" | 14900 | 13300 | 11600 | 9490 | 7420 |

| 500 | 20" | 18500 | 16600 | 14600 | 11900 | 9300 |

| 600 | 24" | 29100 | 26000 | 22100 | 17300 | 13500 |

| 700 | 28" | 39800 | 36000 | 30000 | 24000 | 20100 |

| 750 | 30" | 46700 | 41400 | 34900 | 27700 | 23400 |

| 800 | 32" | 55600 | 47600 | 40000 | 31700 | 26700 |

| 900 | 36" | 70400 | 61200 | 52200 | 42400 | 35300 |

| 1000 | 40" | 88800 | 75900 | 64700 | 52700 | 46600 |

| 1100 | 44" | 108000 | 92100 | 78400 | 67700 | 58700 |

| 1200 | 48" | 129000 | 112000 | 97500 | 83300 | 77300 |

| 1300 | 52" | 153000 | 132000 | 116000 | 99300 | -- |

| 1400 | 56" | 186000 | 153000 | 139000 | -- | -- |

| 1500 | 60" | 221000 | 178000 | 161000 | -- | -- |

| 1600 | 64" | 253000 | 206000 | 194000 | -- | -- |

| 1800 | 72" | 321000 | 266000 | -- | -- | -- |

| 2000 | 80" | 398000 | 353000 | -- | -- | -- |

| 2200 | 88" | 501000 | 435000 | -- | -- | -- |

| 2400 | 96" | 599000 | -- | -- | -- | -- |

| 2600 | 104" | 718000 | -- | -- | -- | -- |

| 2800 | 112" | 838000 | -- | -- | -- | -- |

| 3000 | 120" | 963000 | -- | -- | -- | -- |

1. The butterfly Valve with flow coefficient in the table above is multilayer hard seal structure, with sealing ring mounted on the disc.

2. One-piece stem.

Note: For sizes and classes not shown, please contact our Sales Department.

| Size (mm) | Pressure | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| DN | NPS | PN0.25MPa | PN0.6MPa | PN1.0MPa | PN1.6MPa | PN2.5MPa | PN4.0MPa | Class150 | Class300 | Class600 |

| 50 | 2" | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ |

| 65 | 2½" | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ |

| 80 | 3" | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ |

| 100 | 4" | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ |

| 125 | 5" | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | △/★/☆ | △/★/☆ |

| 150 | 6" | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | ●/△/★/☆ | △/★/☆ | △/★/☆ |

| 200 | 8" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ |

| 250 | 10" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ |

| 300 | 12" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ |

| 350 | 14" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | -- |

| 400 | 16" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | -- |

| 450 | 18" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | -- |

| 500 | 20" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | -- |

| 600 | 24" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | -- |

| 700 | 28" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | ★/☆ | ★/☆ | -- | -- |

| 750 | 30" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | ★/☆ | ★/☆ | -- | -- |

| 800 | 32" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | ★/☆ | ★/☆ | -- | -- |

| 900 | 36" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | -- | ★/☆ | -- | -- |

| 1000 | 40" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | -- | ★/☆ | -- | -- |

| 1050 | 42" | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | △/★/☆ | -- | ★/☆ | -- | -- |

| 1100 | 44" | △/★ | △/★ | △/★ | △/★ | △/★ | -- | △/★ | -- | -- |

| 1200 | 48" | △/★ | △/★ | △/★ | △/★ | △/★ | -- | △/★ | -- | -- |

| 1300 | 52" | △/★ | △/★ | △/★ | △/★ | -- | -- | △/★ | -- | -- |

| 1400 | 56" | △/★ | △/★ | △/★ | △/★ | -- | -- | △/★ | -- | -- |

| 1500 | 60" | △/★ | △/★ | △/★ | △/★ | -- | -- | -- | -- | -- |

| 1600 | 64" | △/★ | △/★ | △/★ | △/★ | -- | -- | -- | -- | -- |

| 1800 | 72" | △/★ | △/★ | △/★ | -- | -- | -- | -- | -- | -- |

| 2000 | 80" | △/★ | △/★ | △/★ | -- | -- | -- | -- | -- | -- |

| 2200 | 88" | △/★ | △/★ | △/★ | -- | -- | -- | -- | -- | -- |

| 2400 | 96" | △/★ | △/★ | △/★ | -- | -- | -- | -- | -- | -- |

| 2600 | 104" | △/★ | △/★ | -- | -- | -- | -- | -- | -- | -- |

| 2800 | 112" | △/★ | △/★ | -- | -- | -- | -- | -- | -- | -- |

| 3000 | 120" | △/★ | △/★ | -- | -- | -- | -- | -- | -- | -- |

| 3200 | 128" | △/★ | -- | -- | -- | -- | -- | -- | -- | -- |

| 3400 | 136" | △/★ | -- | -- | -- | -- | -- | -- | -- | -- |

| 3600 | 144" | △/★ | -- | -- | -- | -- | -- | -- | -- | -- |

| 3800 | 152" | △/★ | -- | -- | -- | -- | -- | -- | -- | -- |

| 4000 | 160" | △/★ | -- | -- | -- | -- | -- | -- | -- | -- |

| Design Standard | GB/T12238/EN593/DIN/GOST | API609, MSS SP-67 | ||||||||

| Pressure-Temperatured Rating | GB/T12224/DIN/GOST | API609 | ||||||||

| Face-Face | GB/T12221 | API609 | ||||||||

| Flange Ends | GB/T9113, DIN3202, EN1092, GOST12815 | ASME B16.1/B16.5/B16.47/BS4504 | ||||||||

| Inspection & Test | JB/T9092, GB/T13927, DIN3230, EN598 | API598 | ||||||||

| Nominal Pressure (MPa) | 0.25 | 0.6 | 1.0 | 1.6 | 2.5 | 4.0 | Class150 | Class300 | Class600 | |

| TEST Pressure (MPa) | Shell Test | 0.375 | 0.9 | 1.5 | 2.4 | 3.75 | 6.0 | 2.93 | 7.58 | 15.0 |

| High Pressure Seal Test | 0.275 | 0.66 | 1.1 | 1.76 | 2.75 | 4.4 | 2.07 | 5.52 | 11.03 | |

| Low Pressure Seal Test | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | |

| Applicable Temperature | -196°C~550°C Different raw material for different work temperature. | |||||||||

| Applicable Medium | Water, oil gas and other causticity medium (Different raw material for different medium) | |||||||||

A pioneer manufacturer & supplier company having good experience in the designing and manufacturing of a new concept instrumentation Valves

Y-21, Khan Real Industrial Estate, N. H. 08, Pelhar, Vasai Phata, Vasai East, Palghar - 401208. INDIA

© Copyright 2024 | All Rights Reserved